Textile Industry Brushes

In recent years, we have witnessed a significant technological development in the textile industry. In this context, even the application of accessories, like brushes, becomes relevant. It is therefore important for these accessories to be manufactured with technology, competence and adequate experience, in line with the product on with they will be applied.

As far as textile industry is concerned, we are able to supply cylindrical, circular and linear brushes with high quality brush frames and covering materials. Brush India brushes also supplies long cylindrical brushes, with low allowance necks and dynamic balancing, in accordance with their use in single applications. This ensures excellent functionality.

Brush India Offer Following Products For Textile Industry:

Brush Roller for Brushing Machine

Application:- For Various Brushing Machine.

Advantages : -

- Innovative brushing roller technology

- All standard diameters from 50 - 500 mm available

- All standard working widths in split and non-split design possible

- Maintenance-free (no ageing, embrittlement, shrinkage); no wear

- Fit for high-speed use thanks to computerised roller balancing

- Absolutely vibration-free running in all speed ranges

- Ready-to-install

- Supporting bushes or connecting flanges to your specifications

- Fast delivery capability, installation advice, replacement service

- Brush Roller Can Be Manufactured Up to 5000mm in length

Brush Rollers for Sueding Machine

Application:- Cloth Finishing Machine (sueding Machine)

Advantages : -

- When using the UltraSoft Brush Roller For Sueding Machine The finishing result is miracles .

The Ultra Soft brush Roller allows covering the maximum angle leading to greater contact area between fabric and abrasive brush Roller. - The new sueding technology using abrasive brushes creates very fine dust compared to conventional sandpaper which creates larger particles that are easier to eliminate.

- The brush process is an economical and technique in improving certain surface properties and is mostly used on-line. The Brush is manufactured as per Customer Drawings and Specification due to various OEM Machine Specification.

The Brush Roller is manufactured on High- Tech European Machine

Brush roller improves: - Finishing Of the Cloth Surface and Create Smoothness Improves the Surface Properties

Brush Roller for Singing Machine

Application:- Gas Singing Machine

Advantages : -

- The Brush Roller opens the Fabric face for more perfectly Burn.

- Heavy Construction of Brush Roller for, Vibration Free operation.

- The Brush Roller is dynamically Balance for High R.P.M.

- The Combination of Nylon with Mexican fiber improves the Brush life (low wear) and can resist on Higher Temperature.

- The Molded Brush Sleeves is made of High graded Polypropylene Material and can be Interchangeable

- The Brush Roller is manufacturer on High tech European Machine to Higher Quality Results

- Drive Arrangement for Brush roller.

- The brush roller for gas singing machine can be made up to 5000 MM in length.

Stenter Brushes

Application :- Stenter Machine for Holding cloth in Pin Bar.

Advantages:- Stenter Brushes are available in Various Sizes and Dimension as per customer Requirememts

Brush Material :- Nylon, Nylon 66 , Pig Bristle, Polyamide, etc

Base material:- Alluminium, High Grade polypropylene , Cast Nylon, Nylon etc

Brush Strips

Application:- Sealing, Cleaning, Removing, Anti Barrier, etc

Advantages : -

- Easy to Fit

- Economical

- Used for Various Application

- Available in Various Sizes and Length ,Color

- Available ex-stock

Brush Rollers for Finishing Machine

Advantages : -

- Innovative brushing roller technology

- All standard diameters from 50 - 500 mm available

- All standard working widths in split and non-split design possible

- Heavy Construction of Brush Roller for, Vibration Free operation.

- The Brush Roller is dynamically Balance for High R.P.M.

- Maintenance-free (no ageing, shrinkage); no wear

- Wide choice of Bristle Material Available

- Ready-to-install Brush Rollers.

- The Molded Brush Sleeves is made of High graded Polypropylene Material and can be Interchangeable

- The Brush Roller is manufacturer on High tech European Machine to Higher Quality Results

- Supporting bushes or connecting flanges to your specifications

- Fast delivery capability, installation advice, replacement service

- Brush Roller Can Be Manufactured Up to 5000mm in length

- Drive Arrangement for Brush roller

Beating Rollers

Application:- For Cloth Beating Machine

Advantages: -

- Innovative brushing roller technology

- Beater Made of Stainless Steel for Corrosion free Long life

- Heavy Construction of Base Shell

- Maintenance-free no wear

- Fit for high-speed use

- Absolutely vibration-free running in all speed ranges

- Ready-to-install

- Fast delivery capability, installation advice, replacement service

- Beating Roller Can Be Manufactured Up to 5000mm in length

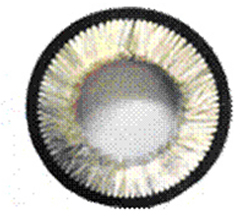

Comber Brushes

Application:- In Textile Combing Machine

Brush Material:- Mexican Fiber

Base Material :- Aluminum and our Specially Developed High Graded Polypropylene Material